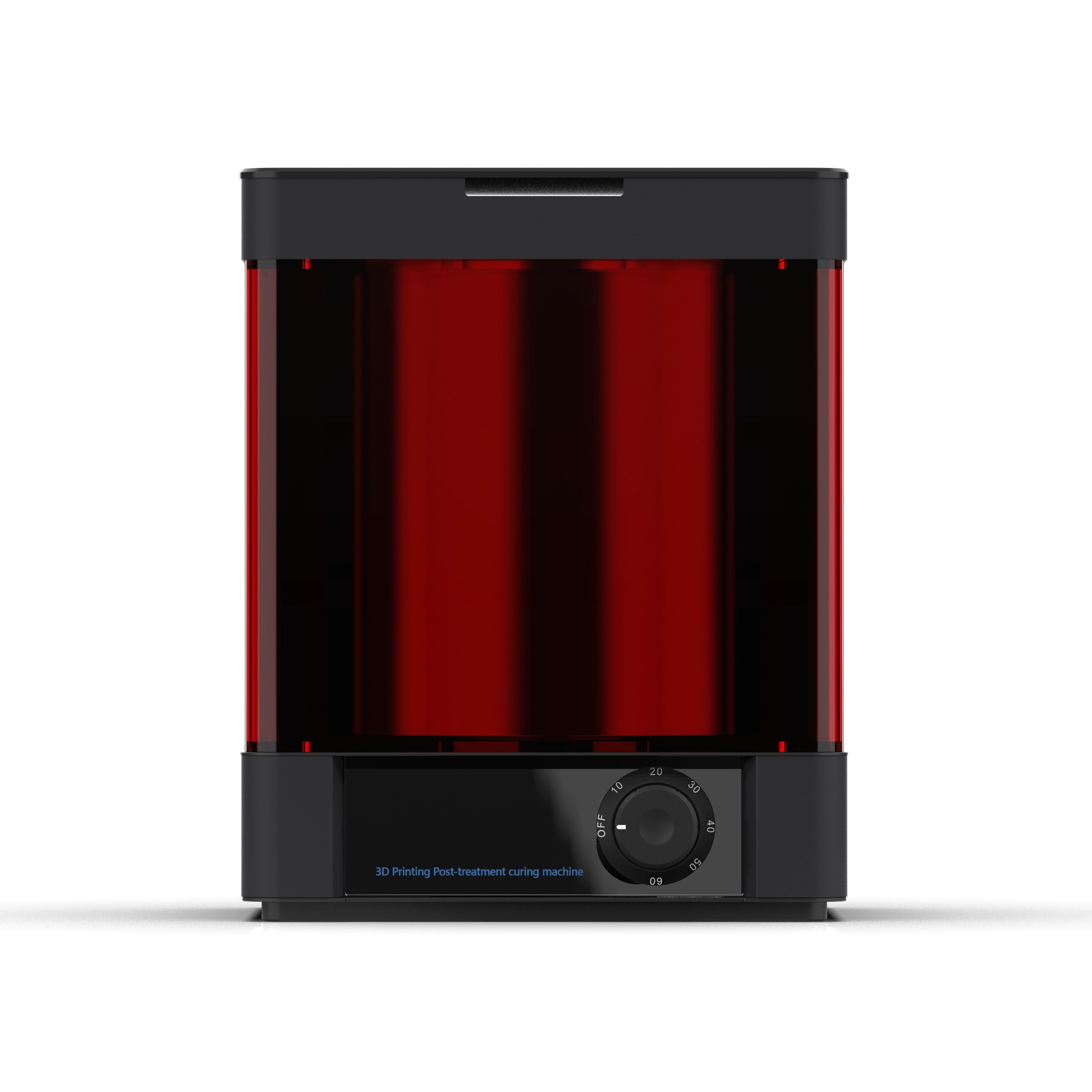

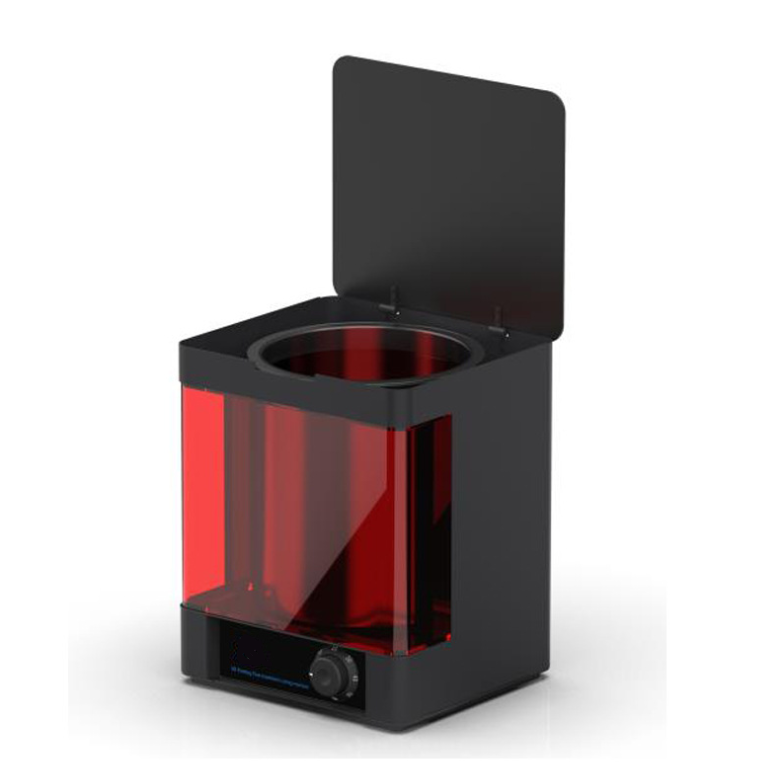

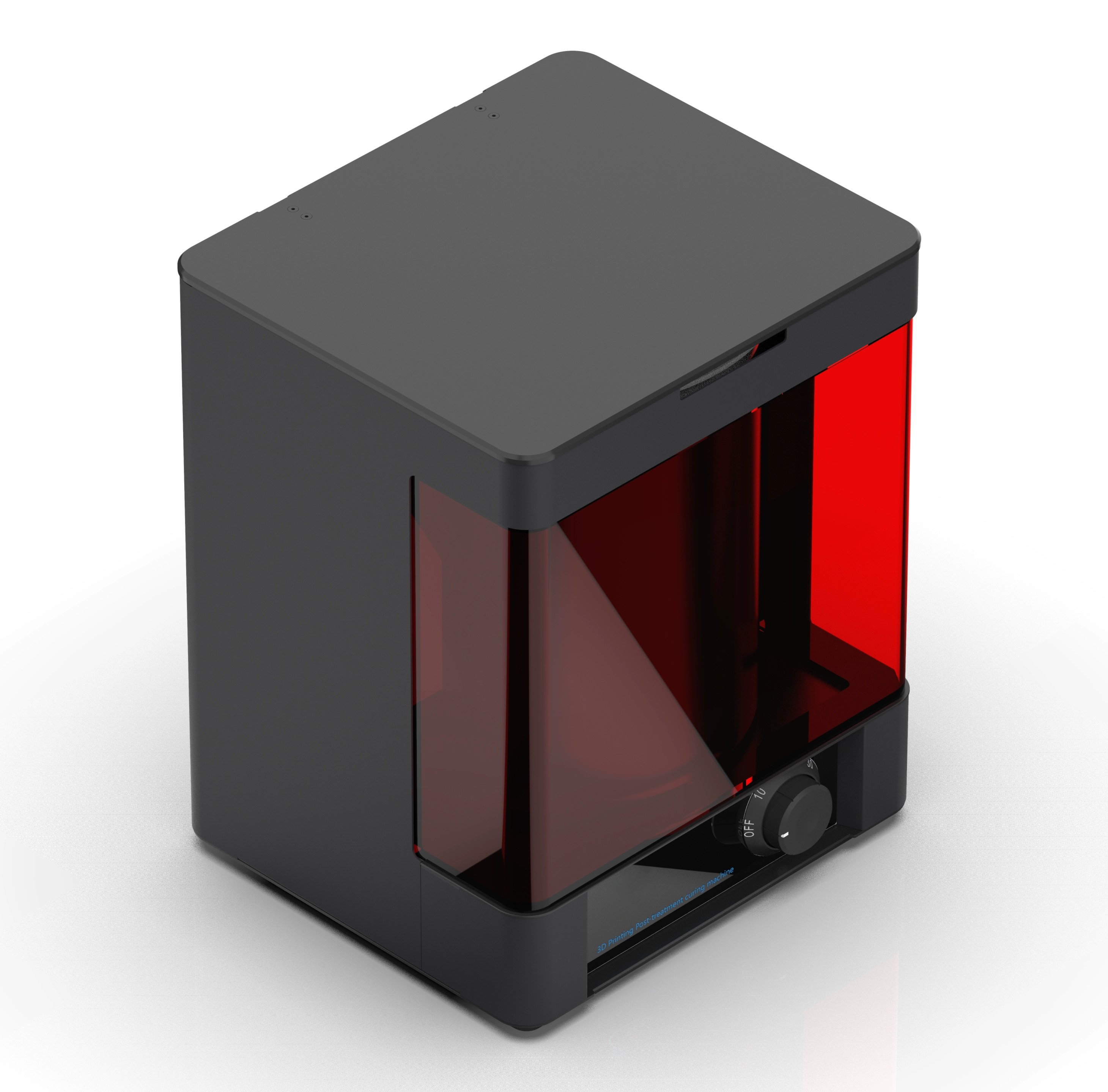

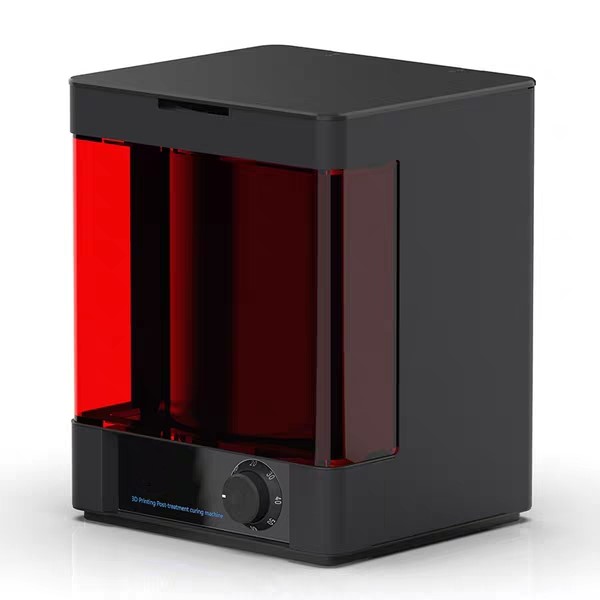

UV Curing Box

Product introduction:

Post-curing treatment equipment, high-quality 405LED, internal rotating tray, fast and uniform curing, one-key start, fixed timing, and the cured surface is smoother.

- Product Description

We are committed to the 3D printing industry,we have our own factory .Everything will be shipped soon and with high quality. Welcome to place order

DESCRIPTION

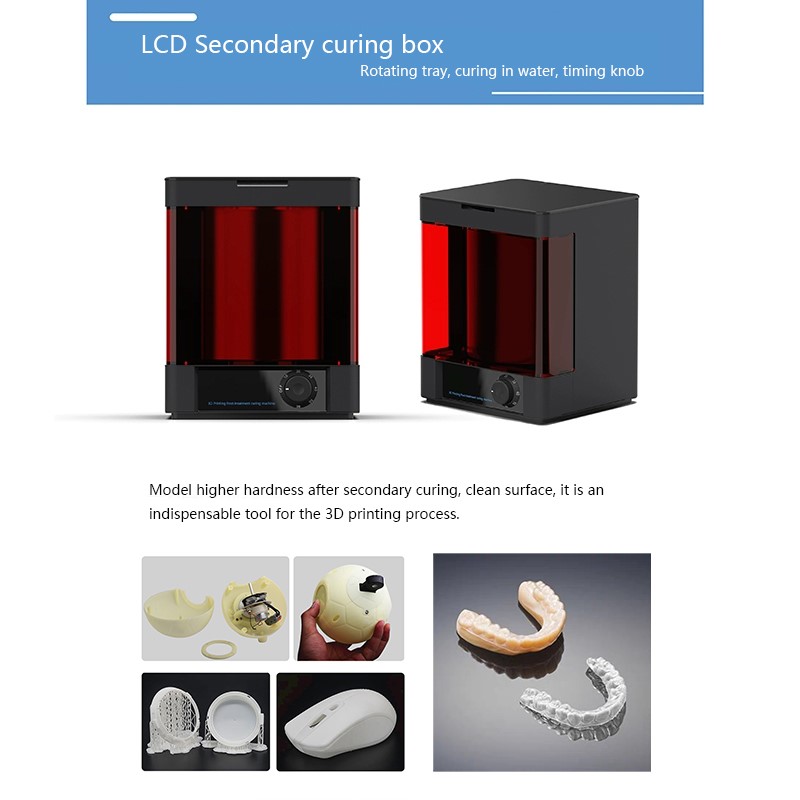

LCD Curing Box

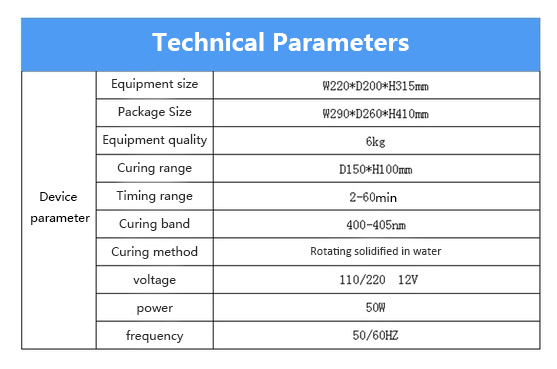

Tesh Specs

Feature

1.Small and light

2. Knob timing

3. Rotate the tray for uniform curing

4. Solidification in water reduces shrinkage deformation and improves

surface hardness

After curing, the material properties of all resins are improved

. Strength enhancement of standard resin . Performance enhancement of engineering resin

. Mold resin burns more fully . Biocompatible resin requires secondary curing

APPLICATION

No matter what you need, please feel free to contact us.

Contact Us : xslightings@xslightings.com

-

The x-axis direction of the print model is offset

Resolvent:

1: The synchronous wheel on the x-axis motor is loose and the jacking screw on the lower synchronous wheel is tightened;

2: The belt is used for a long time and becomes loose. It can be tightened with elastic buckle.

-

How to replace the consumables in printing

Resolvent:

When printing filling or supporting, rotate the knob anticlockwise on the main interface of the display screen to adjust the printing rate FR100% to 10%. After the printing speed drops, press and hold the extrusion spring clip to quickly pull out the old consumables, and then load the prepared new consumables into the printer (note that the consumables should be inserted in place). Then adjust the printing rate to 30% - 40% to see if it can print normally, and then adjust the printing rate to 100% after everything is normal.

-

Leveling steps while printing

Resolvent:

When printing, rotate the knob anticlockwise to reduce the FR100% (printing rate) on the screen to 30%, and the printing speed will decrease. When printing the bottom layer, you can gently touch the printed consumables to see whether they are glued to the platform. If not, it means that the gap between the nozzle and the platform is too large. Adjust the platform here until the consumables near here can stick to the platform In other places.