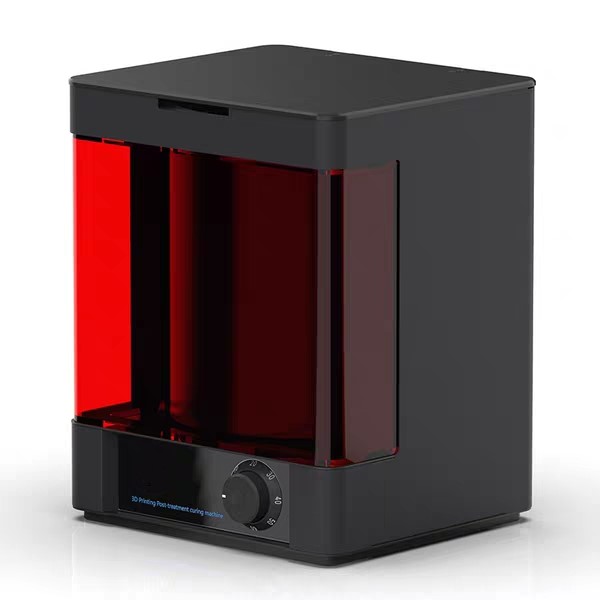

Cube Post-curing C3

Product introduction:

Curing and cleaning, light curing 3D printer curing post-treatment, dry resin preheating and secondary light curing box trinity.

- Product Description

We are committed to the 3D printing industry,we have our own factory .Everything will be shipped soon and with high quality. Welcome to place order

DESCRIPTION

Cube Post-curing C3

Curing washing machine light curing 3D printer curing drying resin preheating secondary

light curing box.

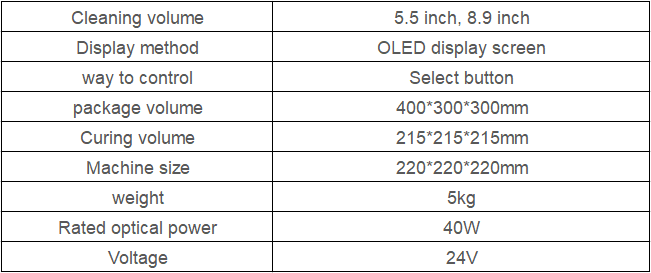

Tesh Specs

Furture

1. Simple and easy to use, one machine for multiple uses, cleaning, curing and drying.

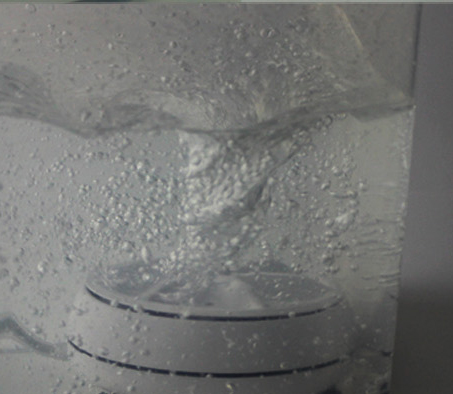

2. Multiple cleaning modes, turbo high-speed cleaning is thorough, ultrasonic vibration

deep cleaning.

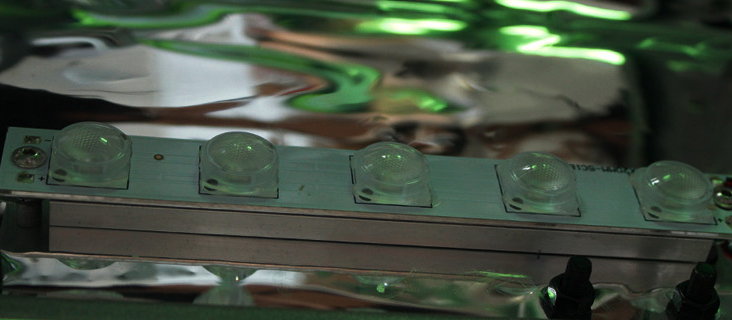

3. The high-power LG UV lamp has a long life. The top lamp is added with two side lamps,

and the rotating platform is efficient and evenly cured. With heating, the curing effect exceeds

the curing mode.

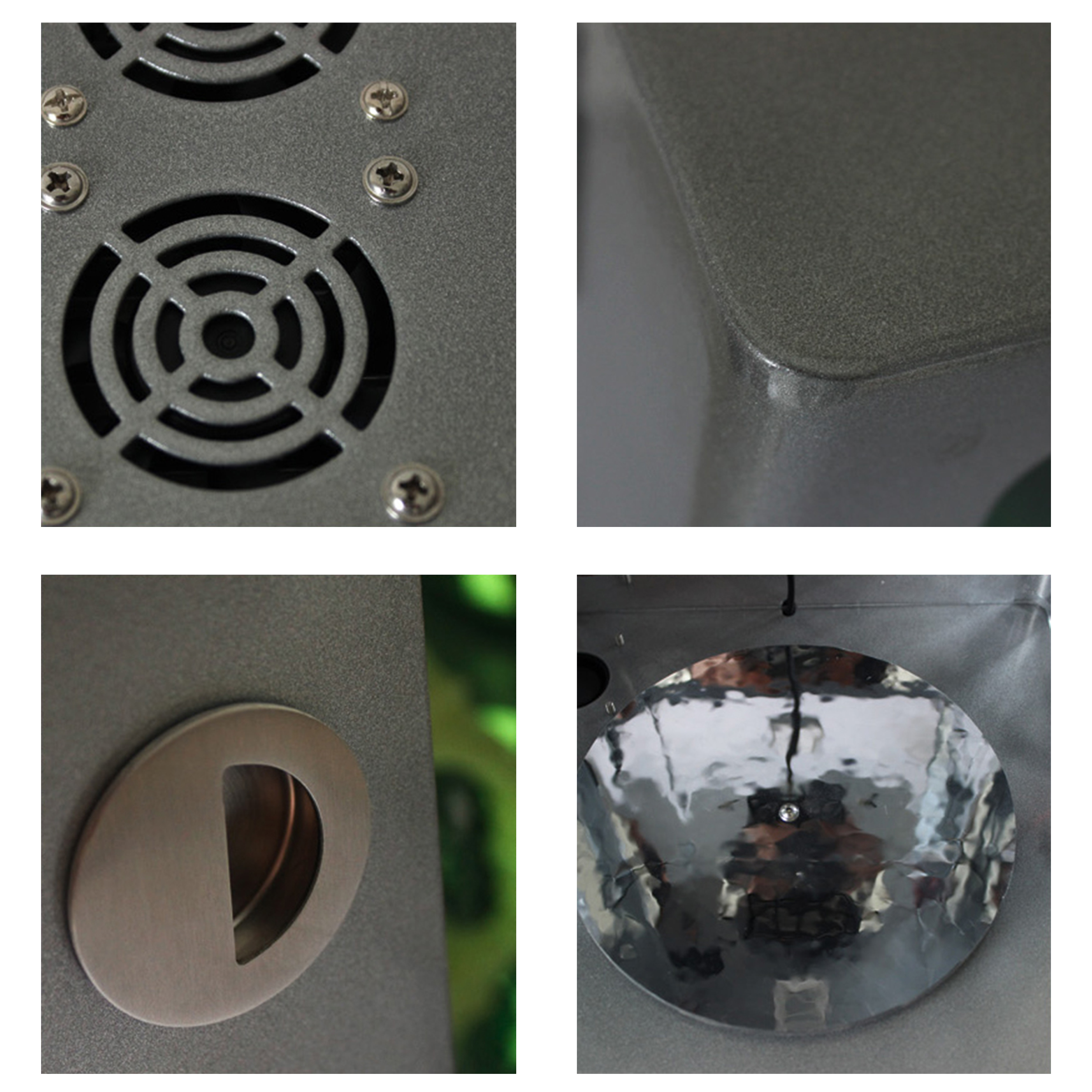

Product Details

Parts List

1.Light Cure curing box

2. Instructions

3.USB turbine

4. Power cord

5. Water tank

6. Basket

APPLICATION

Professional knowledge

. The role of curing and preheating: reducing deformation and curing uniformly

During the post-curing process, the resin model is fully exposed to 405nm light, thereby increasing

the strength and hardness of the material. Heating can accelerate the formation of more chemical

bonds, so that post-curing becomes more efficient, thereby optimizing material properties.

. Photosensitive resin preheating

When the temperature is low, the photosensitive resin will be more viscous due to its inherent

characteristics, which will affect the printing success rate (broken, non-forming, non-sticky, etc.). At

this time, you can use the advanced heating mode of Light Cure for preheating .

. FDM Consumables Drying

Dry the moisture-absorbing PLA\ABS\PC\PVA and other good consumables to make FDM printing

recover better.

. Dry immediately after cleaning

Do not dry the alcohol on the surface of the cleaned model, under the unidirectional irradiation of the

curing lamp, it will form a strong pull between the surface and the internal stress and cause cracks.

. Choice of lotion

Please use high-concentration alcohol (above 95%) to clean the model. IPA isopropyl alcohol (≥95%)

can make the cleaning process easier and does not damage the chemical structure of the resin cured

product itself, but IPA is an industrial solvent with a pungent taste Nose, please use it with caution.

No matter what you need, please feel free to contact us.

Contact Us : xslightings@xslightings.com

-

The x-axis direction of the print model is offset

Resolvent:

1: The synchronous wheel on the x-axis motor is loose and the jacking screw on the lower synchronous wheel is tightened;

2: The belt is used for a long time and becomes loose. It can be tightened with elastic buckle.

-

How to replace the consumables in printing

Resolvent:

When printing filling or supporting, rotate the knob anticlockwise on the main interface of the display screen to adjust the printing rate FR100% to 10%. After the printing speed drops, press and hold the extrusion spring clip to quickly pull out the old consumables, and then load the prepared new consumables into the printer (note that the consumables should be inserted in place). Then adjust the printing rate to 30% - 40% to see if it can print normally, and then adjust the printing rate to 100% after everything is normal.

-

Leveling steps while printing

Resolvent:

When printing, rotate the knob anticlockwise to reduce the FR100% (printing rate) on the screen to 30%, and the printing speed will decrease. When printing the bottom layer, you can gently touch the printed consumables to see whether they are glued to the platform. If not, it means that the gap between the nozzle and the platform is too large. Adjust the platform here until the consumables near here can stick to the platform In other places.