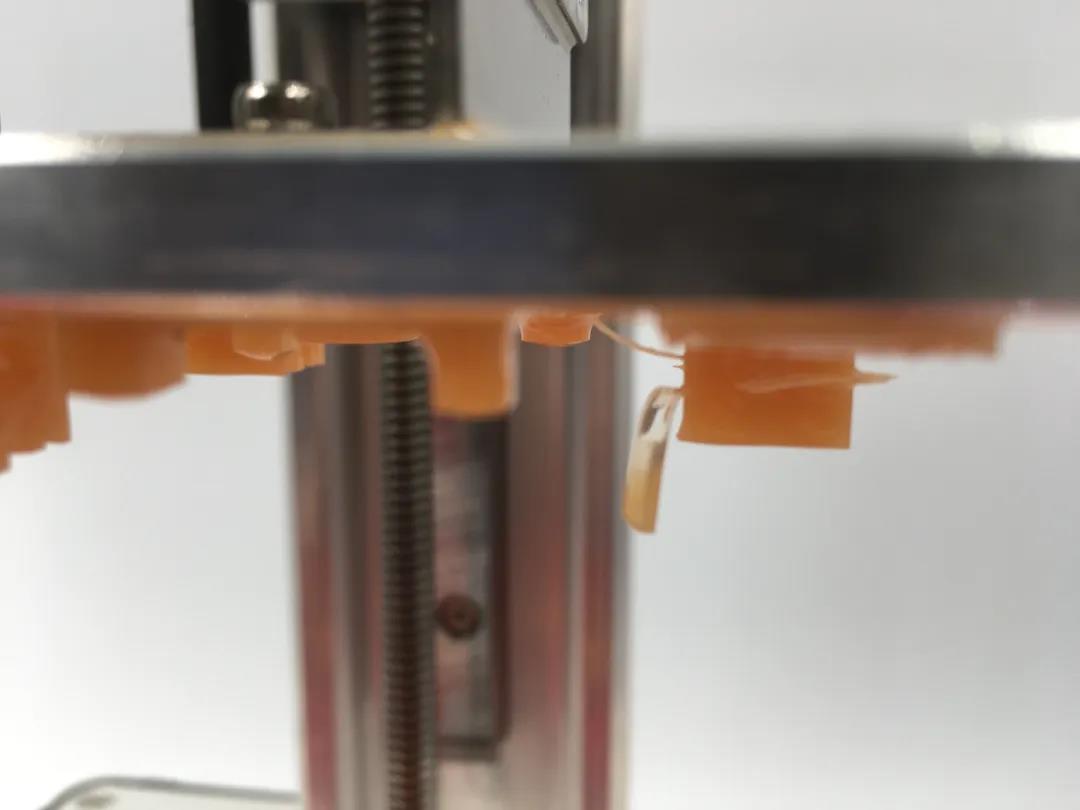

Understand the "kelp" in light-curing 3D printing (sheet/floc)

"Kelp" is generally a sheet or floc that is suspended in a liquid resin or attached to a model or support surface. The

formation of "kelp" is usually due to some newly generated layers that are not attached to the previously generated

layers, which is different from the bottoming ( about bottoming: how to solve the problem of model bottoming in

pull-up light curing printing ? ) , These newly generated layers are not adhered to the release film, but fall into the

liquid resin. As the molding platform moves up and down, the liquid surface shakes, and may still be suspended in the

liquid resin, or stuck on the model or Support surface.

Knowing the causes of "kelp", it is easy to find out which factors caused the formation of "kelp".

Exposure time

Insufficient exposure time may cause the layer to fail to fully cure, so that some semi-cured flocs continue

to accumulate in the liquid resin, or part of the layer directly falls into the liquid resin due to adhesion problems,

and the accumulation becomes more flakes or Floc.

support

Support is not added in place, especially for suspended and bridge positions. If there is no support in these

positions, or the support cannot play its due role, these positions will fall due to lack of support during the printing

process. If the bottom is not attached to the release film, it will accumulate into more flakes or flocs with the printing

process.

light source

Attenuation of the light source will also cause problems with insufficient curing energy, and the above-

mentioned semi-curing and adhesion problems will occur, forming flakes or floccules in the liquid resin, or sticking to

the model or supporting surface.

Screen contrast

The contrast of the screen is low, resulting in some areas of the screen where no image is output may also have

light passing through. Although the intensity is not high, it will gradually accumulate to form flakes or flocs.

- What are the key points of choosing dental 3D printer?2020-07-28 16:55:35

- How to rent and purchase dental 3D printers2020-07-28 16:57:00

- What are the key points of choosing DLP 3D printer?2020-07-28 16:58:46

- Scientists develop practical new 3D printing resin optimized for visible light2020-09-22 09:20:37

- 3D printing helps the digital transformation of the dental industry2020-09-22 09:00:50

- Mechanical problems of z-axis instability in LCD 3D printing2020-09-07 15:13:43

- The world’s first case of four bionic cat paws, amazing my 3D printing2020-09-07 15:03:32

- The same is an industrial 3D printer, where is the difference between "they".2020-08-29 09:04:32

- 4 ways to solve the problem of "level stratification"2020-08-13 10:35:22

- Born specifically for designers, the new 3D printer Stratasys J826™ is available!2020-08-03 15:59:50

- Nature: Electrostatic jet deflection 3D printing sub-micron structure, the speed is 1,000 to 10,000 2020-08-03 15:04:17