Biomechanically validated additive manufacturing special insole for diabetic foot

The United States Centers for Disease Control and Prevention (CDC) reported that in every 1,000 diabetic patients,

the rate of lower extremity amputation (LEA) due to complications first appearing in the feet is 18.4%. However,

LEA is preventable, and can be prevented and treated through therapeutic shoes or orthopedic insoles. Due to the

differences in the individuality of patients' feet, mass-produced orthopedic insoles cannot adapt to every patient,

so the use of additive manufacturing can solve this problem.

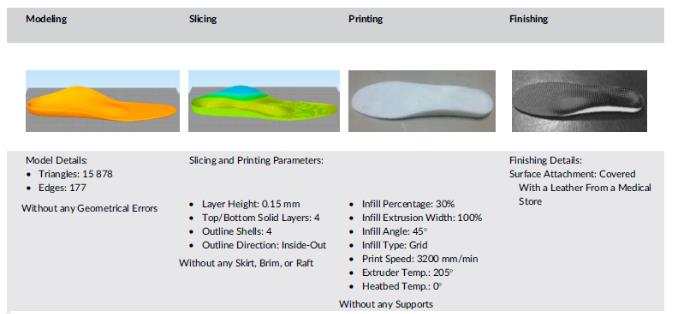

Recently, researchers at Kocaeli University in Turkey scanned the foot with a three-dimensional scanner, obtained a

personalized insole model based on the foot model, and used the fused deposition (FDM) process to manufacture

a special insole for diabetic feet. The mechanical properties of the E-SUN polymer wire printed samples used in the

FDM process and the traditional ethyl vinyl acetate (EVA) samples were tested, and the insoles printed by the FDM

process and the traditional EVA insoles were not synchronized in the walking process ( The finite element analysis

and comparison of standing position, heel on the ground, flat sole, standing position, and heel off the ground)

were carried out to optimize the FDM printing process to ensure the biomechanical function of the diabetic foot

insole under the FDM process.

Figure 1 Step-by-step additive manufacturing of insoles based on FDM process

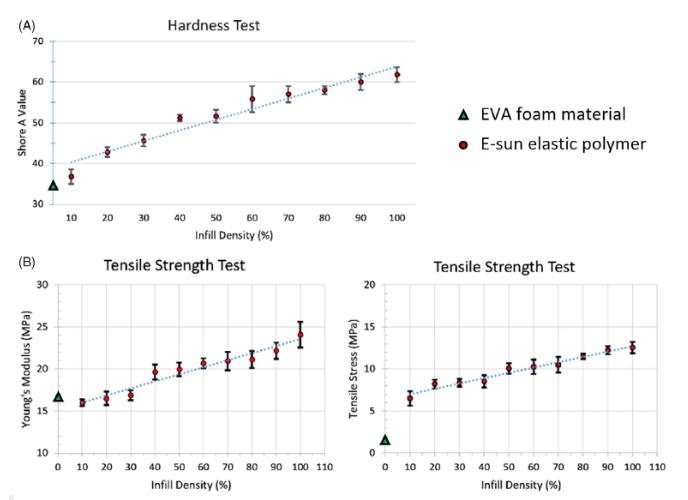

Figure 2 Test results of mechanical properties of ethyl vinyl acetate (EVA) and additive manufacturing samples (filling

density of 10-100% respectively), (A) hardness test results and (B) tensile strength test results

Mechanical performance experiments show that the tensile stress of each sample of 3D printing with different filling

densities varies between 6.5 and 12.5 MPa. The tensile stress of EVA foam is 2.1 MPa, which is lower than any 3D

printed samples.

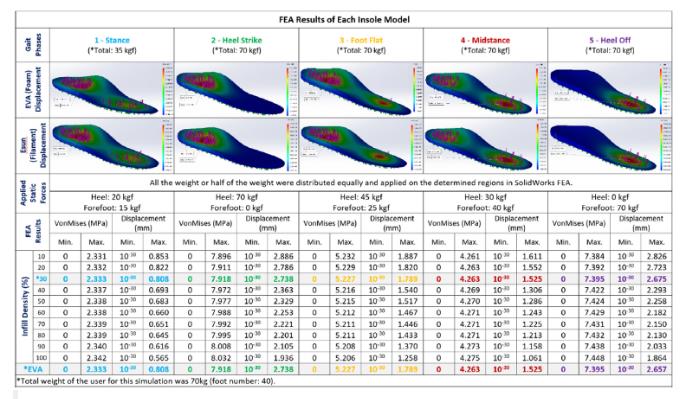

Figure 3 Finite element analysis (FEA) of each printed insole model and traditional EVA foam model in the gait phase

The finite element analysis results show that under the same external force, as the filling density of the insole model

increases, the material displacement value decreases at each gait stage, while the equivalent stress increases. The

results show that the insole model with a filling density of 30% and the insole model of EVA foam have the same

finite element analysis results, thereby ensuring the biomechanical function of the additive manufacturing insole.

The cost of traditional processing insoles is US$31.92, and the processing time is 15 hours. A pair of dedicated

insoles manufactured by fused deposition (FDM) cost US$6.88 and the processing time is 8 hours. This method

greatly reduces the cost and time.

- What are the key points of choosing dental 3D printer?2020-07-28 16:55:35

- How to rent and purchase dental 3D printers2020-07-28 16:57:00

- What are the key points of choosing DLP 3D printer?2020-07-28 16:58:46

- Scientists develop practical new 3D printing resin optimized for visible light2020-09-22 09:20:37

- 3D printing helps the digital transformation of the dental industry2020-09-22 09:00:50

- Mechanical problems of z-axis instability in LCD 3D printing2020-09-07 15:13:43

- The world’s first case of four bionic cat paws, amazing my 3D printing2020-09-07 15:03:32

- The same is an industrial 3D printer, where is the difference between "they".2020-08-29 09:04:32

- 4 ways to solve the problem of "level stratification"2020-08-13 10:35:22

- Understand the "kelp" in light-curing 3D printing (sheet/floc)2020-08-13 09:31:29

- Born specifically for designers, the new 3D printer Stratasys J826™ is available!2020-08-03 15:59:50

- Nature: Electrostatic jet deflection 3D printing sub-micron structure, the speed is 1,000 to 10,000 2020-08-03 15:04:17