Ultra Clear Resin

Product introduction:

Ultra Clear Resin XSR13 resin used for fluid and module manufacturing, specially for optic, lighting and all semi-transparent spare parts. High transmittance Low contraction percentage Low smell, non toxic

- Product Description

We are committed to the 3D printing industry,we have our own factory .Everything will be shipped soon and with high quality. Welcome to place order

DESCRIPTION

Engineering Resin

Tesh Specs

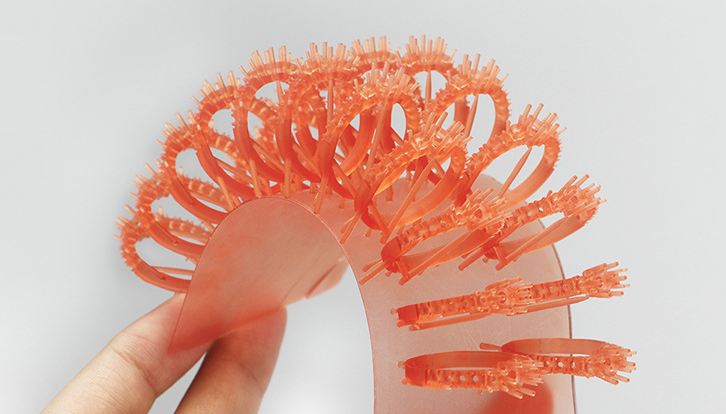

Ultra Clear Resin XSR13 have super toughness comparing with other material, such toughness

resin can be used as bending and compressing spare parts, flexible characteristics fit for multiple

soft touch material as ergonomics.

Super toughness; Low contraction percentage; Low smell, non toxic

Ultra Clear Resin Print model Picture

Ultra Clear Resin Inspection Certificates

Feature

1. LCD molding resin

Professionally optimized for LCD weak light source molding, higher printing efficiency than LCD/

DLP/SLA compatible resins on the market.

2.High model accuracy

Low shrinkage, stable printing size, high printing accuracy, fine texture of the model, smooth

surface, three-dimensional presentation of details.

3.High curing speed

XINSHAN resin increases the printing speed and shortens the curing time while ensuring the

strength of the molded parts and not excessive shrinkage, so as to improve the printing efficiency

of the LCD machine as much as possible.

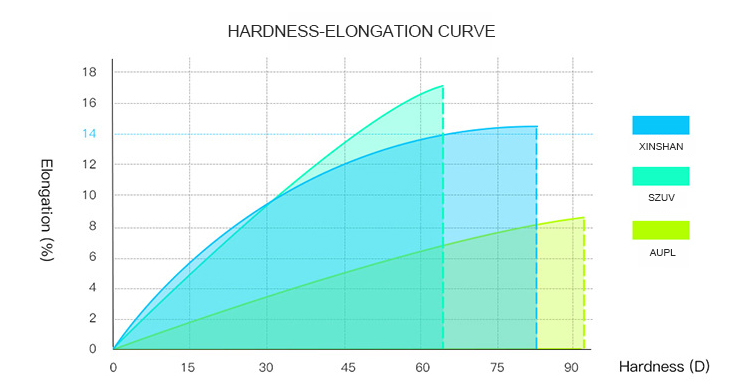

4.Strong and balanced

The finished model has good strength and flexibility, excellent molding and impact resistance.

Materials that are too hard are more likely to shatter after being bumped, but materials that are

too flexible are more prone to stretch deformation and breakage when printing details, which

affects molding accuracy and aesthetics.

5.Bright and pure colors

The color is bright, pure and full, in line with the international G7 standard

APPLICATION

Application display

Proof of concept, functional testing, mold manufacturing for prototype industry,

consumer products, medical, display, education, and other professional markets.

Precautions

1.Shake well before use. It is forbidden to use resin in places exposed to a lot of sunlight;

2.Do not take orally, keep away from children, wear gloves before use, avoid direct contact with

skin, and keep indoor ventilation;

3.Do not get into the eyes, if accidentally touched, rinse with plenty of water as soon as possible.

If you feel unwell, seek medical advice promptly;

4.The printed resin model needs to be cleaned with high-concentration alcohol (above 95% is

recommended, the higher the better) for about 30 seconds;

5.Do not pour the used resin in the trough back into the unused resin, and do not leave the resin

in the trough for a long time without using it;

6.(If you don't use it for a long time, you can put the resin into the container and keep it sealed

and shading with a plastic wrap) to prevent the resin from being polluted and affecting the

printing effect;

Storage method:

1.Store in a dark place at room temperature. Sunlight contains ultraviolet rays, which will cure the

photosensitive resin; it is not affected by ultraviolet light under test light;

2.It is recommended to store at an ambient temperature of 15℃-35℃, the lower the temperature,

the higher the resin viscosity.

3.Keep sealed to avoid excessive dust or damp, affecting the print quality

No matter what you need, please feel free to contact us.

Contact Us : xslightings@xslightings.com

-

The x-axis direction of the print model is offset

Resolvent:

1: The synchronous wheel on the x-axis motor is loose and the jacking screw on the lower synchronous wheel is tightened;

2: The belt is used for a long time and becomes loose. It can be tightened with elastic buckle.

-

How to replace the consumables in printing

Resolvent:

When printing filling or supporting, rotate the knob anticlockwise on the main interface of the display screen to adjust the printing rate FR100% to 10%. After the printing speed drops, press and hold the extrusion spring clip to quickly pull out the old consumables, and then load the prepared new consumables into the printer (note that the consumables should be inserted in place). Then adjust the printing rate to 30% - 40% to see if it can print normally, and then adjust the printing rate to 100% after everything is normal.

-

Leveling steps while printing

Resolvent:

When printing, rotate the knob anticlockwise to reduce the FR100% (printing rate) on the screen to 30%, and the printing speed will decrease. When printing the bottom layer, you can gently touch the printed consumables to see whether they are glued to the platform. If not, it means that the gap between the nozzle and the platform is too large. Adjust the platform here until the consumables near here can stick to the platform In other places.