Desktop NC V3.5

Product introduction:

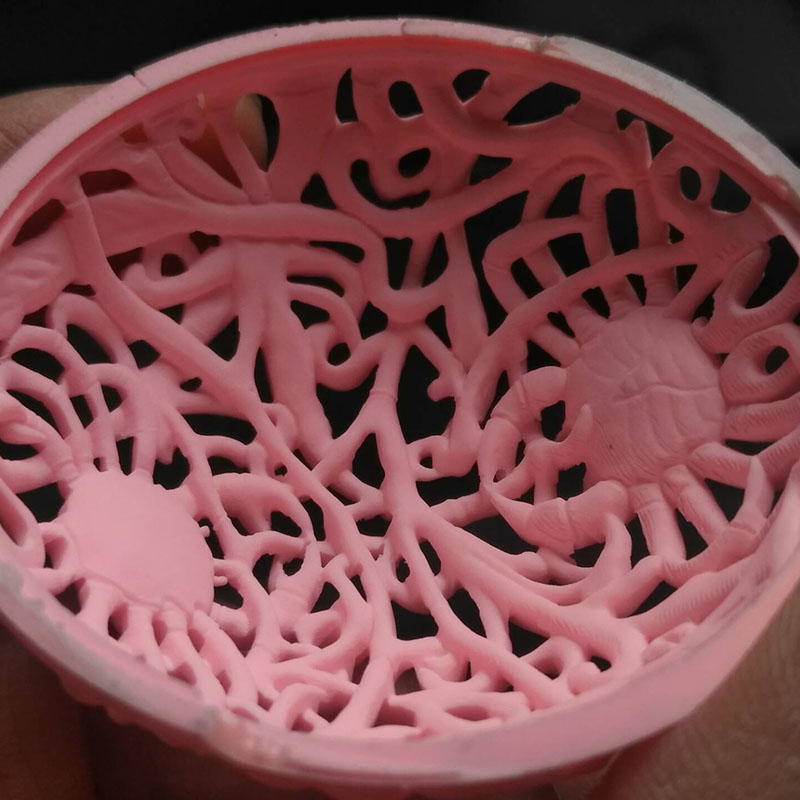

Desktop NC supports a variety of consumables, not only supports common plastic proofing, but also supports milling of aluminum alloy, wood, copper, gold, silver, wax, and other materials. Users can also change cutters as needed for different materials. No need for wrench operation when replacing the head and rotor, which is very convenient.

- Product Description

We commit to desktop processing equipment manufacturers, all products with high quality & service. Welcome to place order

DESCRIPTION

Desktop NC V3.5

1. Introduction

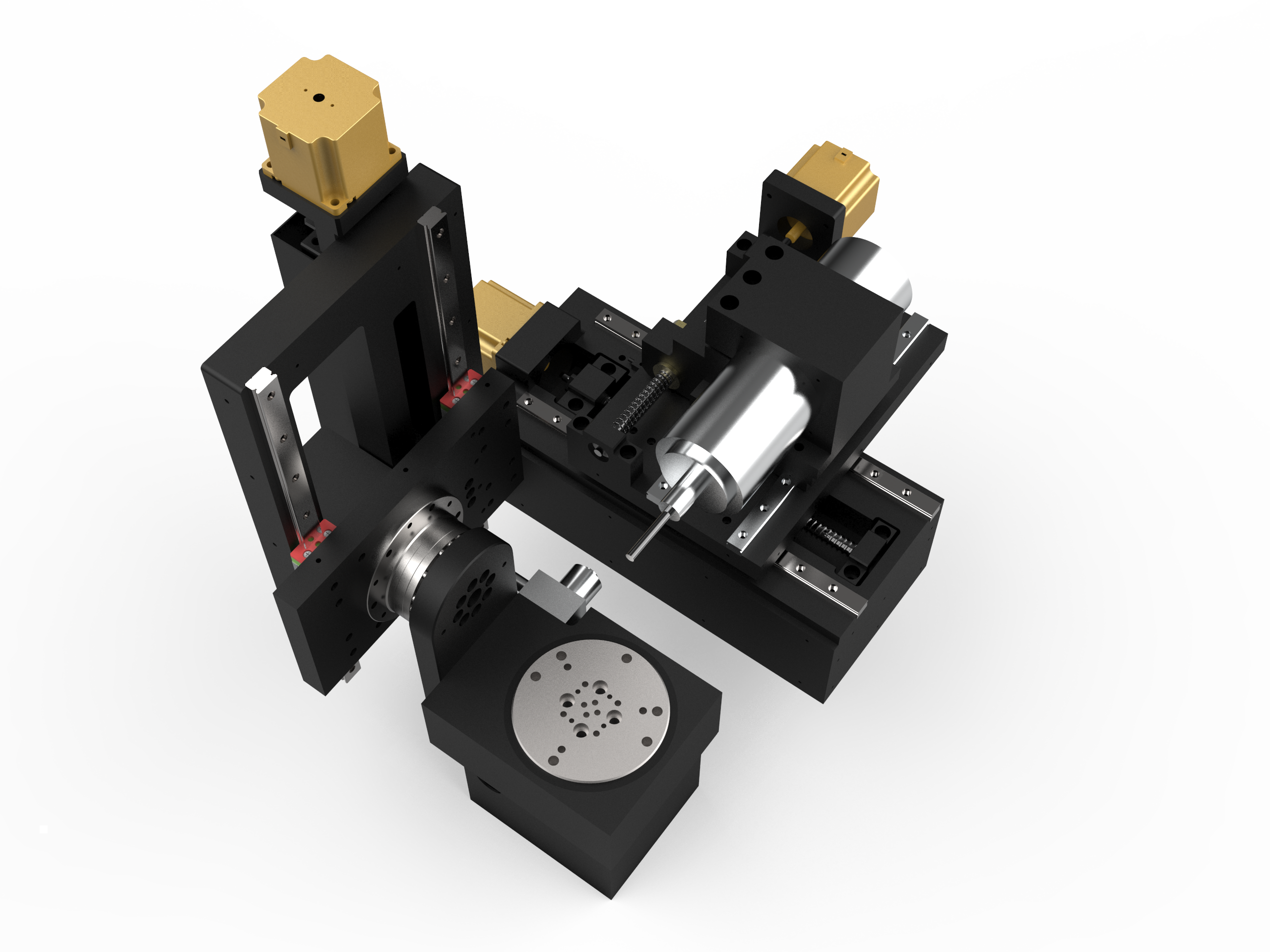

Desktop NC is a desktop five-axis engraving machine produced to satisfy geeks, CNC professional education, and low-cost design and manufacturing. The whole machine can be freely placed on the desktop for operation and use, and the process from design to finished product can be completed quickly with low operating costs. As a desktop 5-axis CNC machine tool, Desktop NC supports Windows system to control. Users can import CAD or CAM format structure drawings through related software for milling. Of course, Desktop NC also supports command control of standard G codes. Regardless of its small size, it is considered that its performance is not eye-catching. Its spindle speed performance of 0-24000rpm is also satisfactory for designers in the professional field.

Desktop NC supports a variety of consumables, not only supports common plastic proofing, but also supports milling of aluminum alloy, wood, copper, gold, silver, wax, and other materials. Users can also change cutters as needed for different materials. No need for wrench operation when replacing the head and rotor, which is very convenient.

Provide smart installation for your 3D printer, After installation, the machine will recognize your 3D

slice model and create the most optimized printing operation for you.

FEATURE

2. Product features

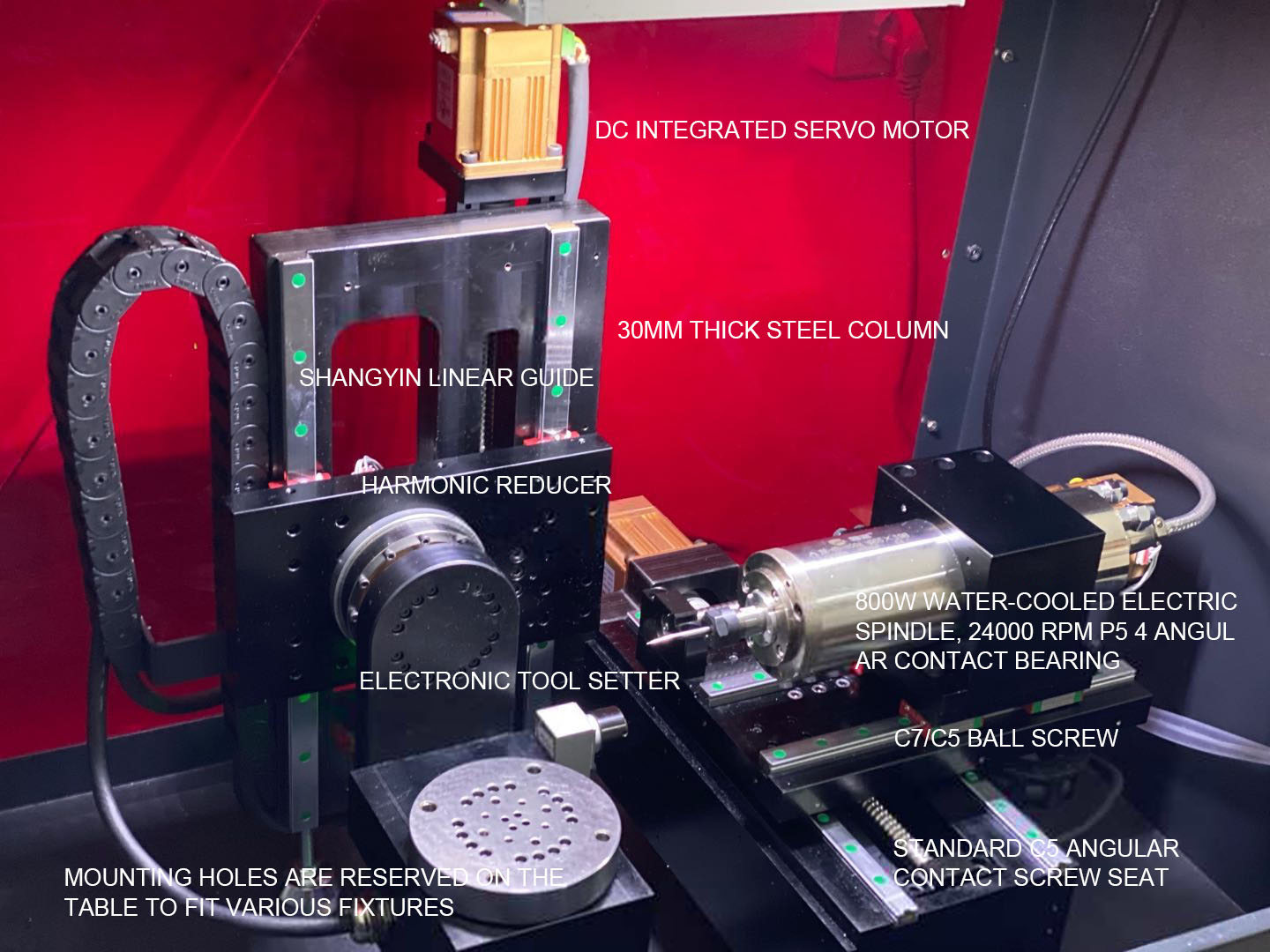

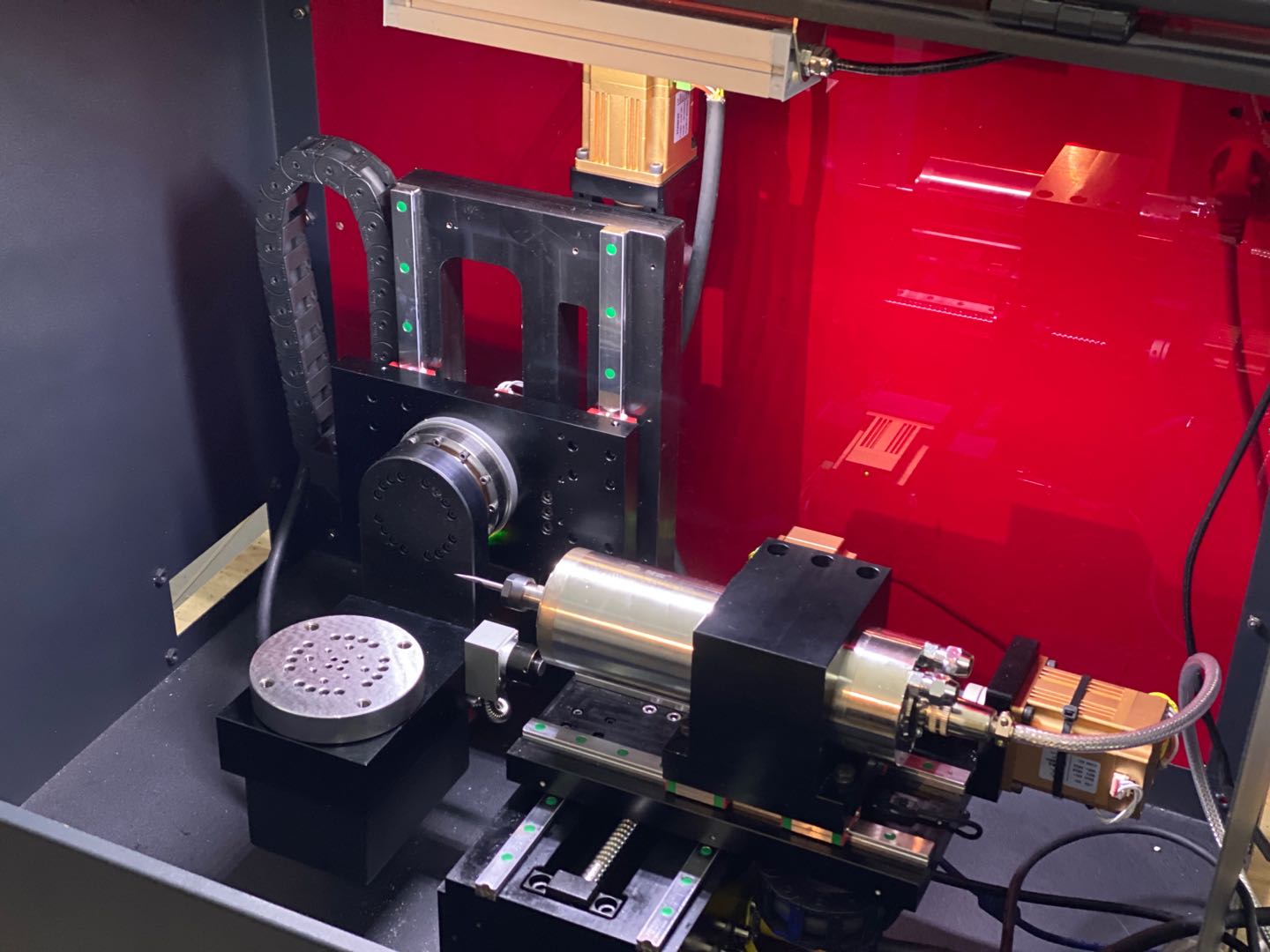

As an iterative product of V3, V3.5 has further improved its machining accuracy and is equipped with an automatic tool setting system.

The rotation axis is upgraded from a worm to a harmonic, the Z axis is optimized to a double guide rail, and the main control board is upgraded,

and the origin of each axis is upgraded to a servo Z0 signal. The spindle is equipped with a 800W water-cooled high-speed electric spindle.

In addition, the sheet metal chassis is designed, the key components are waterproof, and the cutting fluid can be sprayed and metal or jade can

be processed.

①It is suitable for campus makers, university innovation studios to produce processed parts, vocational colleges integrated CNC professional

training, and enterprise scientific research units to process small parts.

②The whole machine weighs only 45kg and occupies a small area. It can be freely placed on the desktop for operation and use, and the

process from design to finished product can be quickly completed with low operatin g costs.

③The application method is simple and professional combination, equipped with video tutorials and paper teaching materials, which not only

meets the entry of CNC beginners, but also me ets the needs of professional learning CNC operators. You can directly use third-party

programming software graphics to directly generate G code programs, or you can manually program , Wide range of processing materials

(copper, aluminum, plastic, wood, Plexiglas and other materials), high processing precision, and the machine is strong, stable and durable.

④It is equipped with a precision high-speed electric spindle 24000rpm, the control card controls the spindle speed, and the spindle motor

power is 800w.

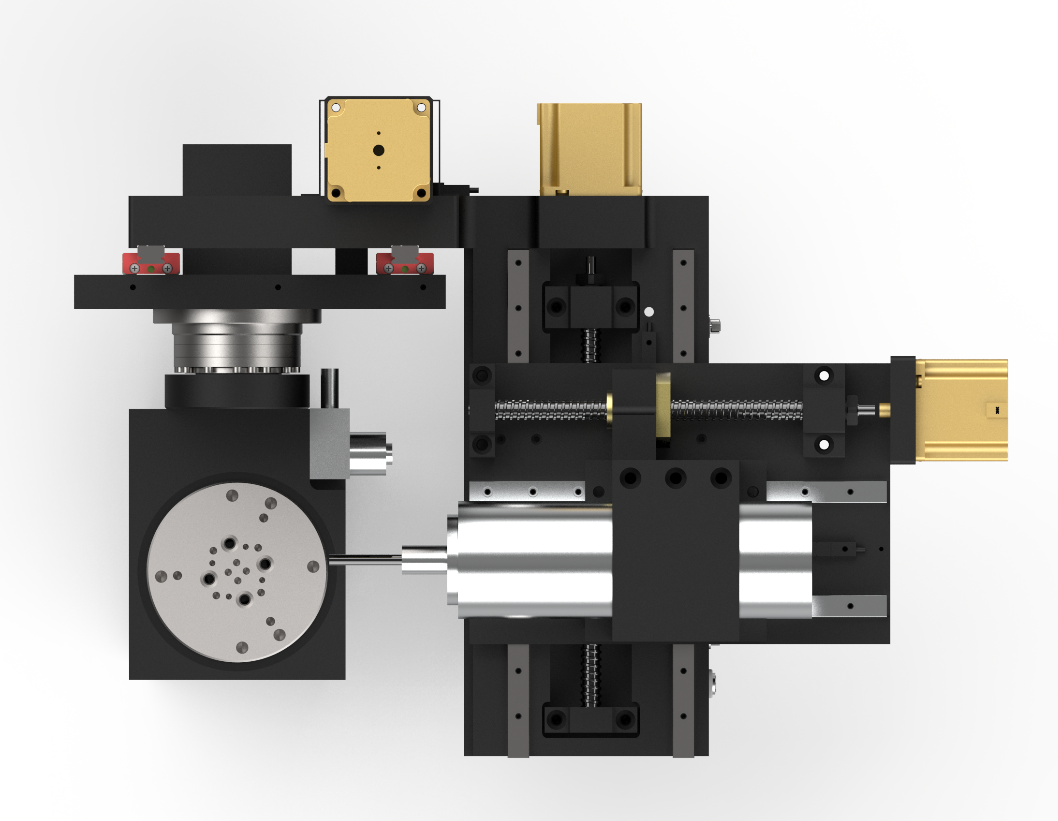

⑤Using nut ball screw, five axis using servo/stepping motor, linear axis using silver guide rail slider.

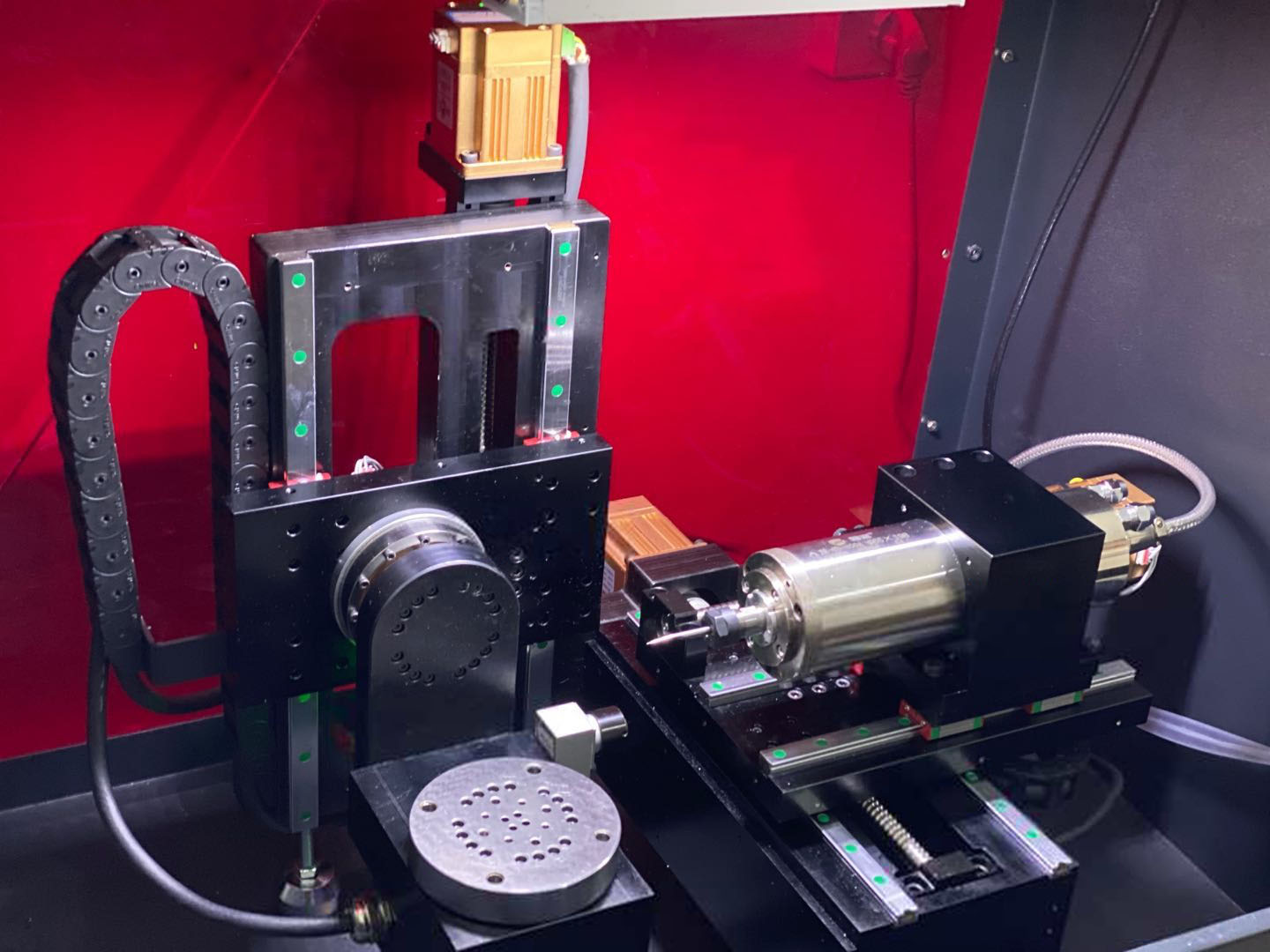

⑥The machine is equipped with a protective cover to isolate dust and noise, and has a dust collection system; casters and horizontal foot

pads are added to facilitate the movement and positioning of the equipment; it is equipped with a 5-axis electronic tool setting system,

which greatly facilitates operation and tool setting.

⑦It adopts ISO standard G code programming, supports M code and S code, supports major software programming, and currently supports

Powermill, UG, Fusion360, HSM post- processing. It has perfect after-sales technical support, provides PM and Vericut machine tool motion

simulation, and provides tool path questions and answers.

Note: The standard five-axis linkage can be added or replaced according to user needs.

TESH SPECS

3. Equipment parameters

Mechanical | |||

Total measurement | 600×400×510mm | Working desk size | Diameter 100mm |

Total weight | 45kg (net weight) | Maximum load of worktable | 5kg |

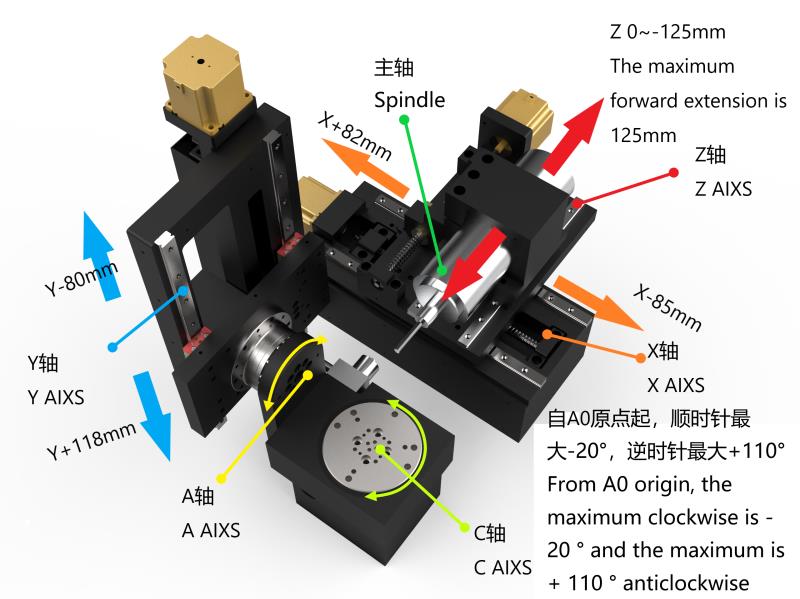

X, Y, Z three axis effective travel | X160×Y200×Z130mm | Effective stroke of A, C rotating shaft | A:-30-120°,C:360° |

Three axis effective | X160×Y200×Z125 | A, C axis rotation axis parameters | 1:80 20 harmonic reducer, hysteresis <1’ |

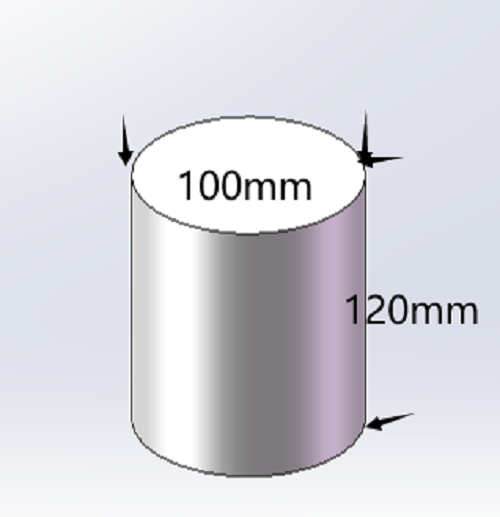

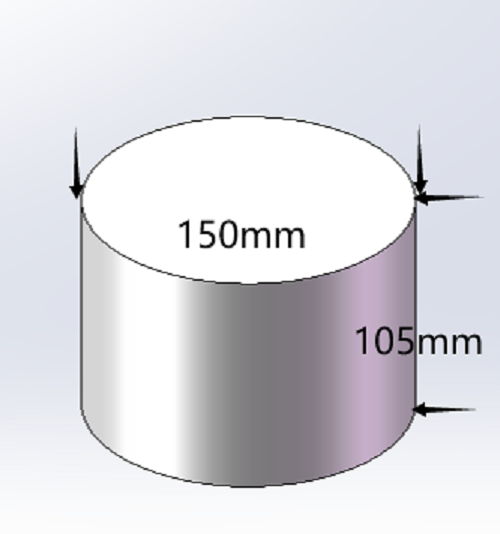

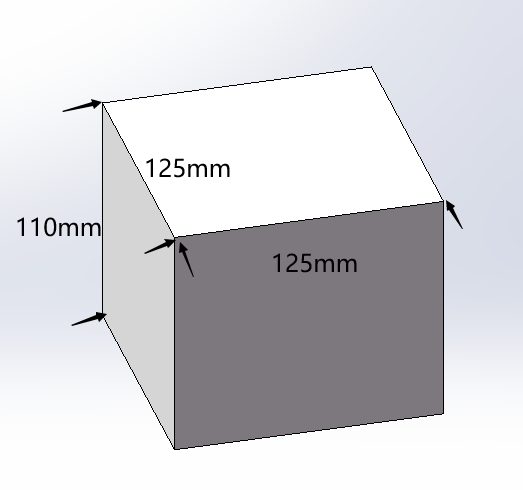

Five-axis machining effective stroke | Cylinder:Φ150×H105mm,Φ100×H120mm,Cube:L125×W125×H110mm | ||

Three-axis machining accuracy | 0.03mm linear axis parallelism & perpendicularity, stroke range 0.02 | Five-axis machining accuracy | 0.05mm five-axis spatial accuracy<0.05 |

Three-axis ball screw | X&Z: 1204 C7, | Linear Guides | X&Z: Hiwin MGN12, |

Frame | 6061T6 Aviation Aluminum + Forced Parts Quenched and Tempered 45 Steel | Processing speed | 4000mm/min |

Spindle model | Φ65mm 800W water-cooled electric spindle 24000r/min | Parts fixture | Steel fixture, reserved holes |

Dust-proof | Organ dustproof + oil seal waterproof and dustproof | Tool diameter & length | ER11 0-8mm,≤75mm |

Processing material | Plastic, wood, aluminum, copper, gold, silver, wax, jade, etc. | ||

Electric control | |||

Motor | 36V DC integrated servo 1500rpm/min | Spindle motor | 800W water-cooled spindle 24000 rpm |

Drive power | 220V input 36V15A output | Control card | USB motion control card |

Home switch | High-precision photoelectric induction with servo encoder Z0 signal to return to zero accurately | ||

Software | |||

Five-axis machine control software | Desktop NC Control | Tool path software | Fusion360(recommend), PowerMill |

APPLICATION

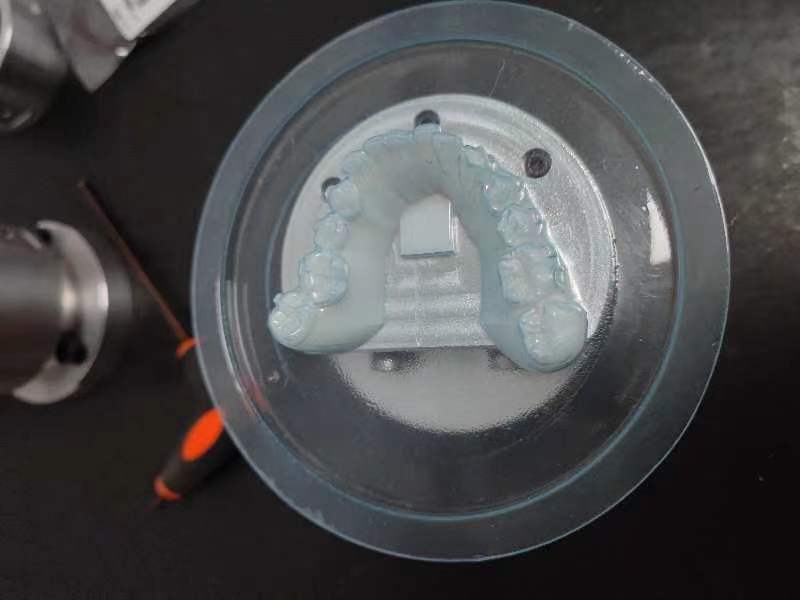

4.Equipment and processing model display

5. Warranty plan

1. The machine equipment warranty period is 6 months.

2. Due to man-made damage, incorrect operation, especially not in accordance with the instruction manual, unauthorized removal and

damage are not guaranteed.

3. Quality problems caused by normal use and damage caused by non-human factors can be directly contacted for maintenance.

4. The warranty plan is to provide free remote guidance for replacement of accessories, and the shipping fee shall be borne by the customer

if it needs to be returned to the factory for repair.

5. After the warranty period has expired, replacement and repair of accessories will be provided at the cost price.

No matter what you need, please feel free to contact us.

Contact Us : xslightings@xslightings.com

-

The x-axis direction of the print model is offset

Resolvent:

1: The synchronous wheel on the x-axis motor is loose and the jacking screw on the lower synchronous wheel is tightened;

2: The belt is used for a long time and becomes loose. It can be tightened with elastic buckle.

-

How to replace the consumables in printing

Resolvent:

When printing filling or supporting, rotate the knob anticlockwise on the main interface of the display screen to adjust the printing rate FR100% to 10%. After the printing speed drops, press and hold the extrusion spring clip to quickly pull out the old consumables, and then load the prepared new consumables into the printer (note that the consumables should be inserted in place). Then adjust the printing rate to 30% - 40% to see if it can print normally, and then adjust the printing rate to 100% after everything is normal.

-

Leveling steps while printing

Resolvent:

When printing, rotate the knob anticlockwise to reduce the FR100% (printing rate) on the screen to 30%, and the printing speed will decrease. When printing the bottom layer, you can gently touch the printed consumables to see whether they are glued to the platform. If not, it means that the gap between the nozzle and the platform is too large. Adjust the platform here until the consumables near here can stick to the platform In other places.