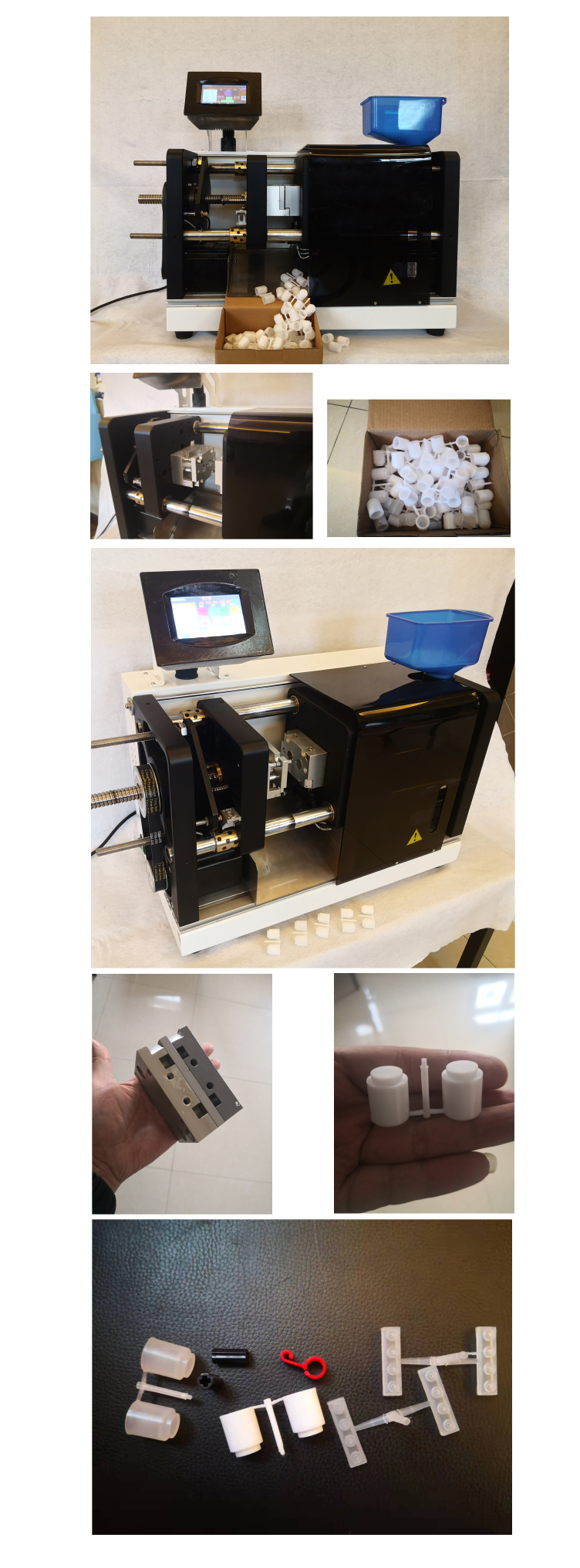

Desktop Injection Machine M1

Product introduction:

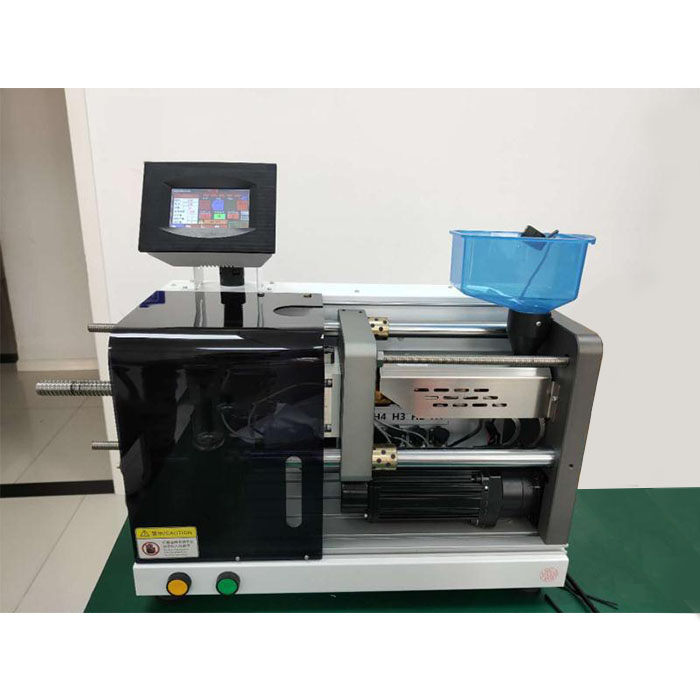

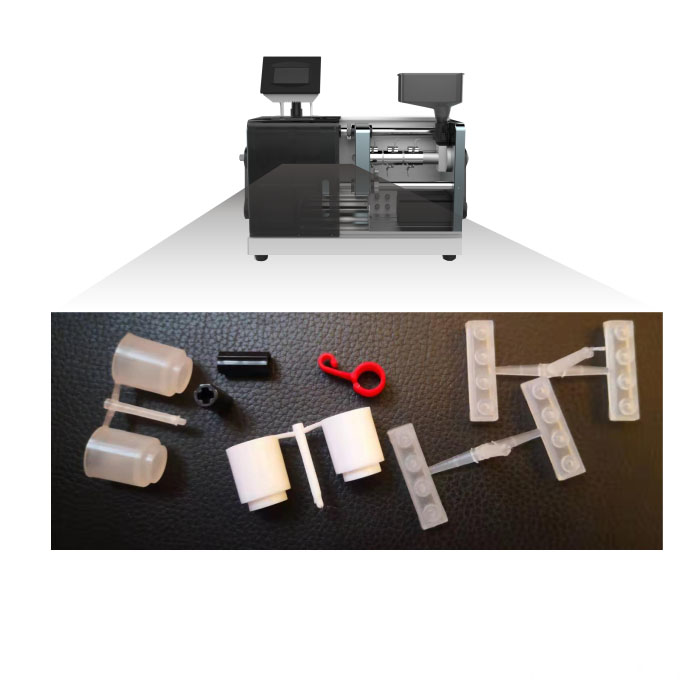

Desktop injection molding machine Mini electric injection molding machine Small batch processing Environmental protection Small plastic parts M1 Create micro injection molding equipment for multi-scenario applications

- Product Description

DESCRIPTION

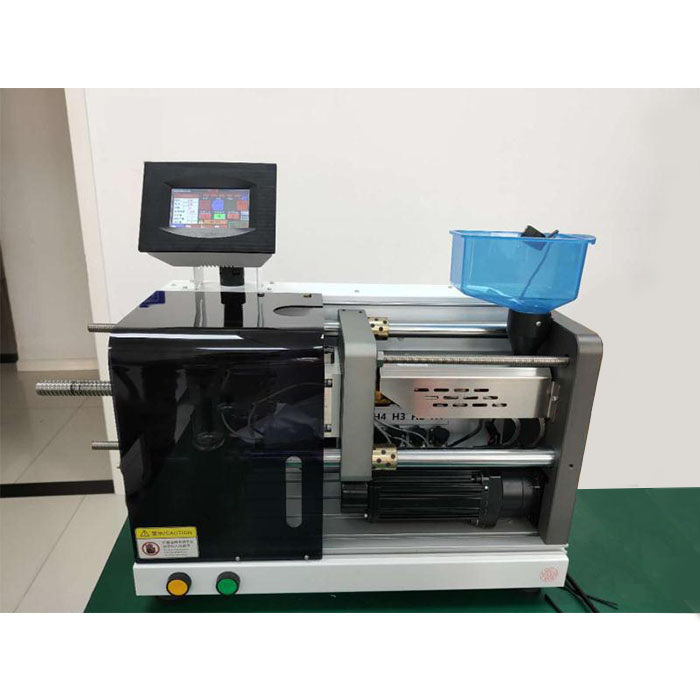

Mini Injection Machine

· Model: M1

· Place of Origin: Mainland China

· Color Classification: M1 Deposit, M1 Final, M1 Machine

· Plastic Machinery Type: All-electric injection molding machine

Desktop injection molding machine Mini electric injection molding machine Small batch processing

Environmental protection Small plastic parts M1

Create micro injection molding equipment for multi-scenario applications

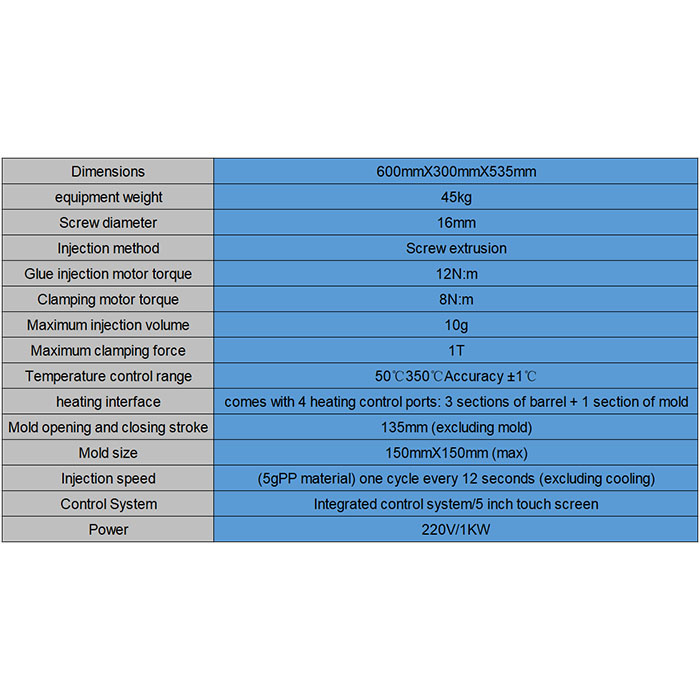

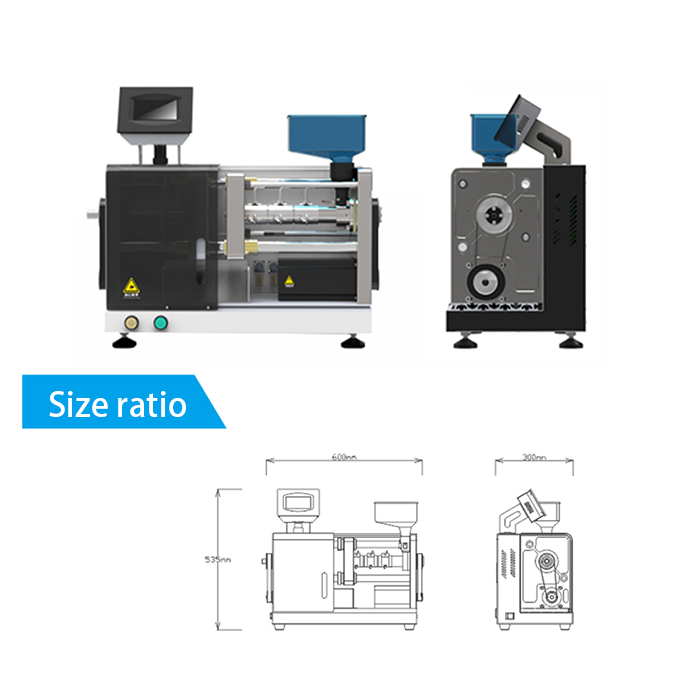

Equipment size 600*300*530mm equipment weight 35KG

Household 220V network power supply rated power 1KW

Tech Specs

Feature

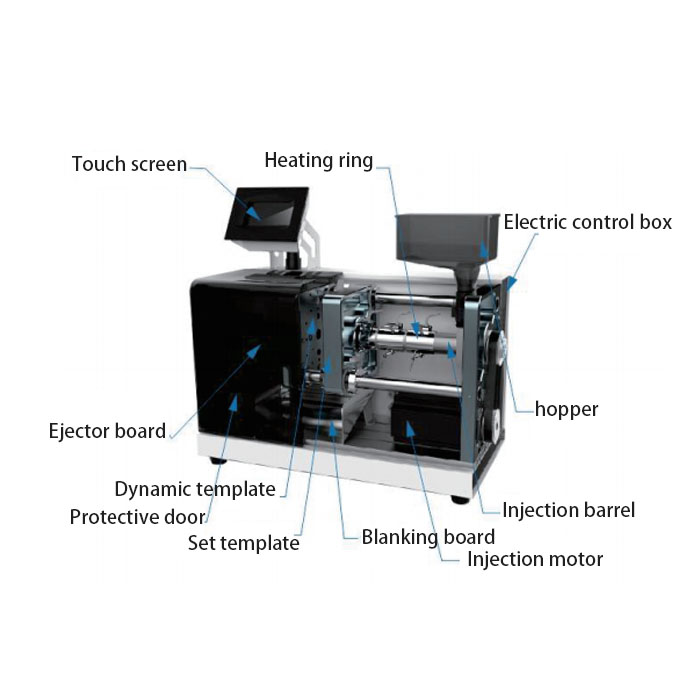

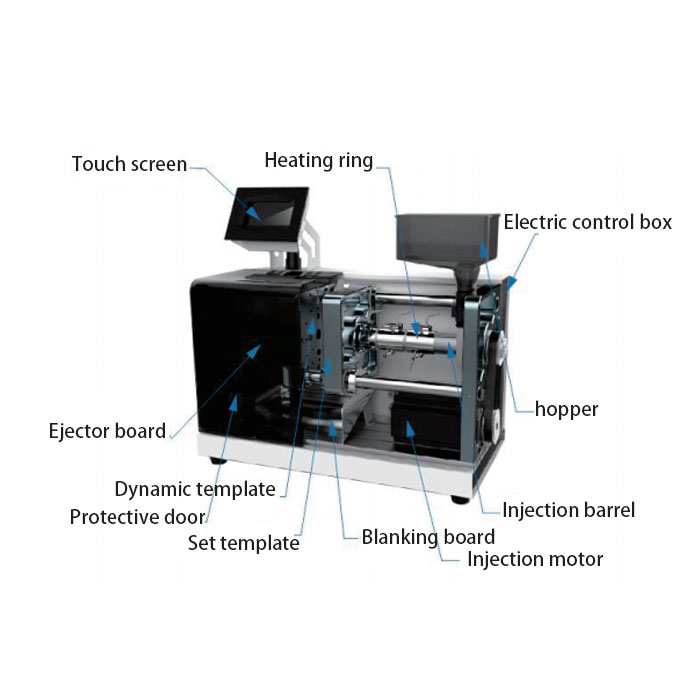

1.Equipment structure

2.Equipment size parameters

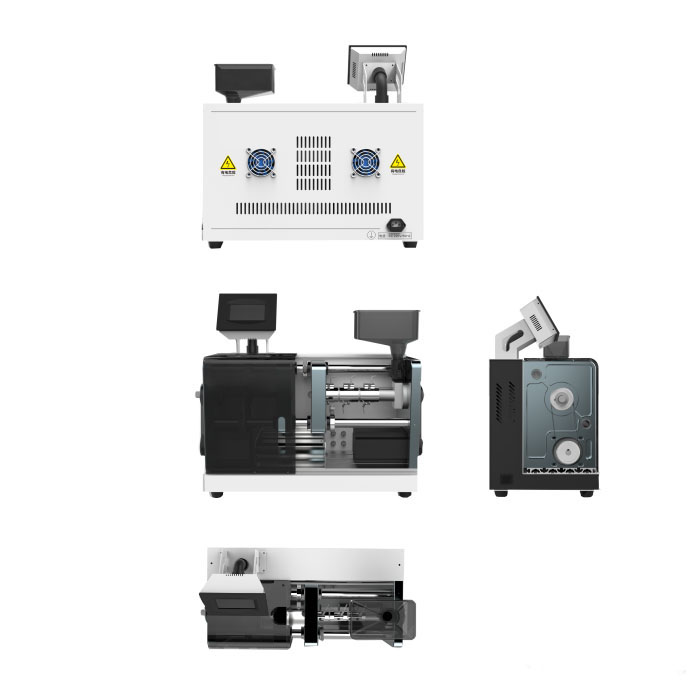

3.Three views of equipment

4.High performance of equipment

High performance, high quality, closed loop, high precision cloth feeding

motor, three-stage PID temperature control

5.Integrated equipment design

No need for external control box with man-machine touch screen software

operation, convenient and safe operation.

No matter what you need, please feel free to contact us.

Contact Us : xslightings@xslightings.com

Precautions:

1. The M1 type equipment only guarantees the normal production of PP\PE\ABS materials,

other materials have not been tested and cannot be guaranteed for normal use.

2. Heating equipment involve high temperatures, please pay attention to safety when used.

3. Do not touch the moving parts of the machinery when the equipment is running.

4. It is forbidden to lift the equipment by one person.

�

1. M1 injection molding machine is a customized model, please consult whether

the injection molding machine can inject your parts before purchasing.

2. The suitable materials for M1 injection molding machine are PP, PE and ABS.

3. The company provides mold design and production for a fee.

-

The x-axis direction of the print model is offset

Resolvent:

1: The synchronous wheel on the x-axis motor is loose and the jacking screw on the lower synchronous wheel is tightened;

2: The belt is used for a long time and becomes loose. It can be tightened with elastic buckle.

-

How to replace the consumables in printing

Resolvent:

When printing filling or supporting, rotate the knob anticlockwise on the main interface of the display screen to adjust the printing rate FR100% to 10%. After the printing speed drops, press and hold the extrusion spring clip to quickly pull out the old consumables, and then load the prepared new consumables into the printer (note that the consumables should be inserted in place). Then adjust the printing rate to 30% - 40% to see if it can print normally, and then adjust the printing rate to 100% after everything is normal.

-

Leveling steps while printing

Resolvent:

When printing, rotate the knob anticlockwise to reduce the FR100% (printing rate) on the screen to 30%, and the printing speed will decrease. When printing the bottom layer, you can gently touch the printed consumables to see whether they are glued to the platform. If not, it means that the gap between the nozzle and the platform is too large. Adjust the platform here until the consumables near here can stick to the platform In other places.